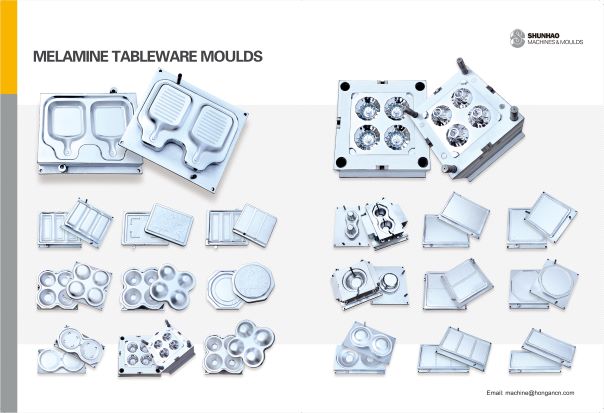

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

item no.:

SH-400TONSproduct orgin:

CHINAbrand:

Shunhaoshipping port:

XIANMEN SEA PORTpayment:

TT/LCMOQ:

1

prev :

Factory Price Melamine Dinnerware Split Machine From Chinanext :

Bamboo Fiber Tableware Compress Machine Melamine Dinnerware Making Machine From Shunhao

Melamine Dinnerware Making Machine From Shunhao

We are the factory of Melamine Dinnerware Making Machine for making trays,bowls,forks,spoons ,mugs,glass.

Single Color Melamine Crockery Compression Machine-MADE IN SHUNHAO

Single Color Melamine Crockery Compression Machine-MADE IN SHUNHAO

We are the factory of melamine tableware compression machine for making trays,mugs,bowls,forks,spoons,ect

2Color Melamine Crockery Moulding Machine From Shunhao

2Color Melamine Crockery Moulding Machine From Shunhao

We are the factory of melamine dinnerware moulding machine for make mugs,glass,forks,spoons,plates,bowls,trays.

Double Color Melamine Tableware Making Machine

Double Color Melamine Tableware Making Machine

We are the factory of melamine tableware making machine for making mugs,spoons,forks,trays,bowls plates,dishes.

Melamine Dinnerware Compression Machine From Shunhao

Melamine Dinnerware Compression Machine From Shunhao

Our machine can be applied in pressing various kinds of melamine dinnerware, such as trays, mugs, plates,chopsticks, spoon, plate, smack-box, starch imitation porcelain tableware plant fiber imitation porcelain tableware, and so on.

PLC Control Uf/Urea Toilet Seat Cover Compression Machine

PLC Control Uf/Urea Toilet Seat Cover Compression Machine

Various Bakelite Molding Operation,Use for UFC and MDF Toilet Seat cover.

Automatic Single Color Melamine Tableware Compression Machine-MADE IN TAIWAN

Automatic Single Color Melamine Tableware Compression Machine-MADE IN TAIWAN

Melamine hydraulic heating press machine Made In China Suitable for melamine tray, plate, bowl, spoon, cup, mug, ashtray melamine toilet seat, and what kinds.

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !