china hospitality expo (che) est un événement annuel pour le secteur hôtelier chinois ancré dans le sud de la Chine, offrant des solutions de guichet ...

hotelex shanghai se tiendra du 1er au 4 avril 2019 dans le nouveau centre d'exposition international de shanghai (2345 longyang road, nouvelle zon...

ukraine salon international de l'industrie du plastique et du caoutchouc durée de l'exposition: du 4 au 7 octobre 2019 lieu: europe - ukraine ...

kazakhstan almaty salon international de la fabrication de matières plastiques et de la technologie des matières premières durée de l'exposition: ...

(2) The 718H is in a pre-hardened state at the factory, and its hardness is HRC28-36.

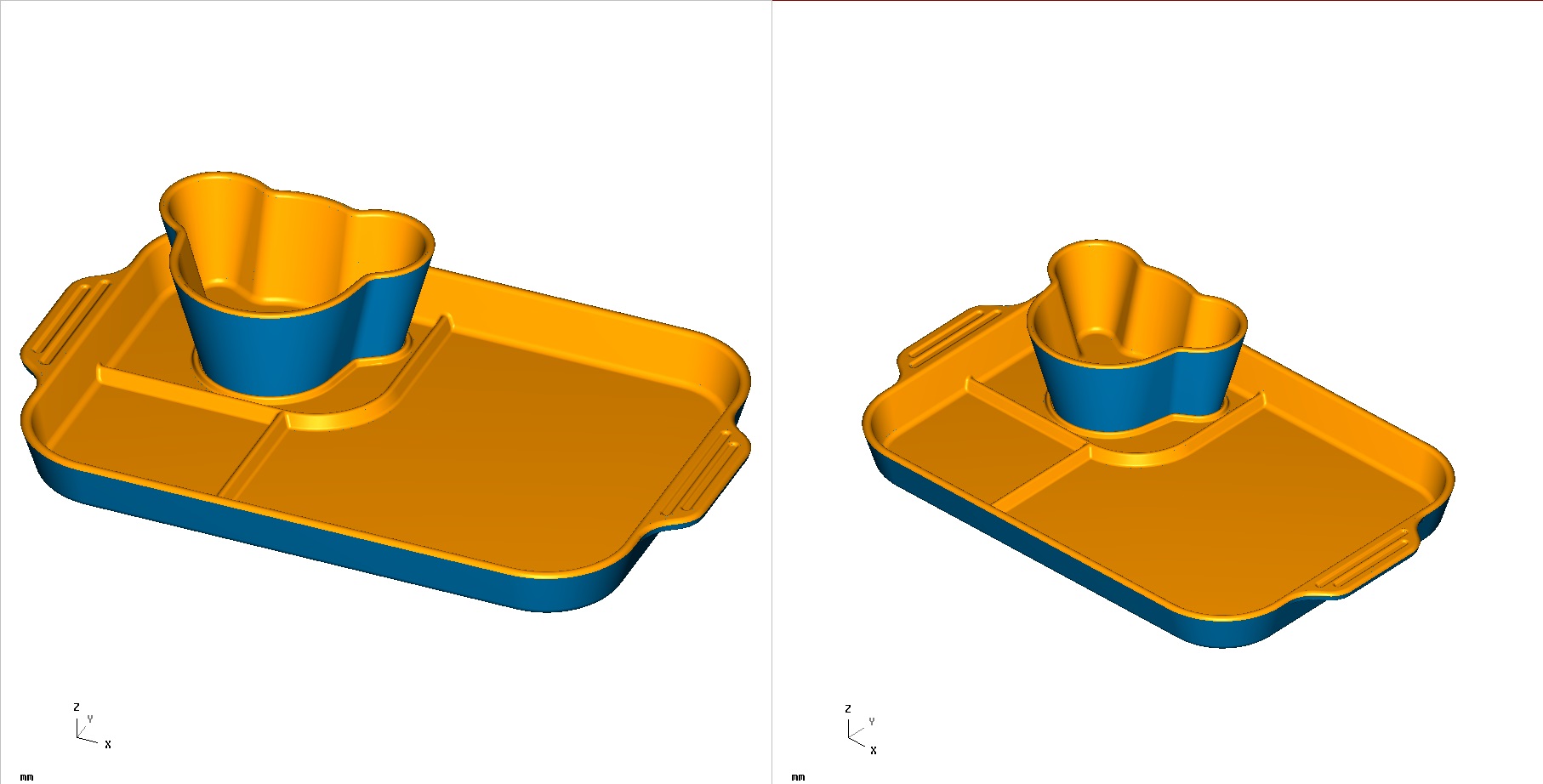

we are the factory of Melamine Tableware Mould,if you need any Melamine Tablewaare Mould ,please kindly contact with me,thanks!

prev :

718H Mould Steel-Introduction 1prochain :

What is the difference between 718H mold steel and P20H mold steel Prix usine mélamine vaisselle de moulage avec double couleur

Prix usine mélamine vaisselle de moulage avec double couleur

notre machine convient à la mélamine, à l'urée, à la bakélite, à la fibre et une autre production de matériaux thermodurcissables de produits de vaisselle.

machine automatique de compression de vaisselle de mélamine

machine automatique de compression de vaisselle de mélamine

cette machine convient à toutes sortes de composé de moulage de mélamine et de composé de moulage d'urée, tel que la plaque de mélamine, le bol de mélamine, le plateau de mélamine.

2color mélamine vaisselle machine de moulage

2color mélamine vaisselle machine de moulage

approprié pour la mélamine, l'urée, la bakélite, production de fibres et autres matériaux thermodurcissables de produits de vaisselle. tel comme bol, tasse, plat, baguettes, cuillère, assiette, boîte à friandises, imitation d'amidon porcelaine vaisselle végétale fibre imitation porcelaine vaisselle plaque fibre imitation vaisselle procelain et ains3

Plc contrôle uf / urée toilettes siège machine de compression

Plc contrôle uf / urée toilettes siège machine de compression

opération diverse de moulage de bakélite, utilisation pour la couverture de siège de toilette d'ufc et de mdf.

bonne machine de préchauffeur de 5kw de prix pour la vaisselle de mélamine

bonne machine de préchauffeur de 5kw de prix pour la vaisselle de mélamine

préchauffeur machine pour la vaisselle en mélamine / mélamine vaisselle machine à mouler / composé de moulage de mélamine

usine de moule de vaisselle de mélamine de Chine avec 4cavity

usine de moule de vaisselle de mélamine de Chine avec 4cavity

usine de moule de vaisselle de mélamine de Chine avec 4cavity

exposition d'atelier

exposition d'atelier

exposition de produits

exposition de produits

émission vidéo

émission vidéo

nos certificats

nos certificats

l\'équipe professionnelle au service !